Product introduction

Cyclone series oil-water separation products are a new generation of efficient sewage treatment equipment developed in cooperation with muddy river Technologies Inc., a famous Canadian water treatment company, for several years. This series of products have obvious removal effects on floating oil, floating oil, COD, BOD, SS and other water pollutants in wastewater. The mechanism of high-efficiency aeration of oxygen enriched microbubbles (particle size of about 5 μ m), adsorption and uplift of surface gas relative to suspended solids is the first new water treatment technology in China. The main equipment of this series of products are:

Oil water separation system of induction cyclones -- Sike mass

Vertical gravity oil-water separation equipment -- seck-vgs

Application scope of Secco products

★ oil recovery and removal

★ removal of solid suspension

★ treatment of oily wastewater in oil refining and petrochemical enterprises

★ recovery of floating oil on the surface of oil field system storage station

★ treatment of oily wastewater from steel rolling plant, steel-making plant and coking plant

★ fiber recovery in paper mill

★ slag flushing water treatment of boiler in power plant

★ treatment and recovery of waste water from food and chemical industry

★ heavy metal recovery in electronic industry

Product introduction

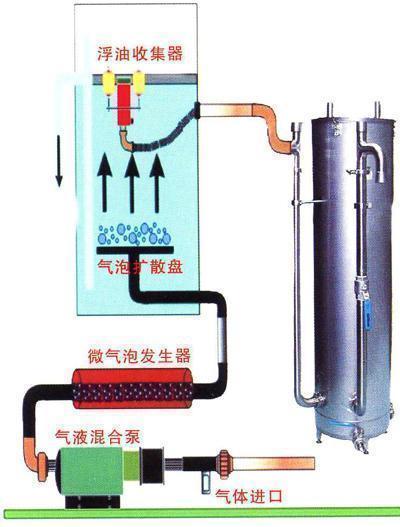

The micro air separation system is a patented solid-liquid and liquid-liquid separation system, which is a revolutionary improvement of traditional air flotation technology. The unique and advanced features of the equipment are mainly manifested in the air flotation stage. By using high-pressure saturated dissolved air water, a large number of high-throughput microbubbles (particle size of about 5 μ m) are released, which are in full contact with the suspended particles, fine oil particles and part of emulsified oil in the wastewater, and are adhered and floated up, so as to achieve the purpose of separation and removal of oil impurities.

Characteristics of SECCO mass oil water separator

1. The performance of microbubbles is good. The bubble size and specific surface can be controlled by adjusting the backflow inlet (negative) pressure and air flow velocity.

2. The air solubility of waste water is high. Microbubble generation system is to treat waste water by pressurized dissolved gas, so that air and waste water can be fully mixed and contacted to form a high dissolved gas and water mixed liquid.

3. The particle size of microbubbles is small. Microbubbles with a particle size of about 5 μ m are produced. The smaller the bubble, the easier it is to adhere to the suspended solids and oil particles in the waste water. The microbubbles produced by the microbubble generation system contact with the wastewater for many times, which makes the air diffuse well and dissolve in the water, so as to achieve the best air flotation separation effect, and finally form the highly concentrated oil residue, which floats to the liquid surface.

4. Automatic energy-saving operation. Through the control of gas-liquid two-phase pressure, the bubble density required by different water quality can be adjusted automatically to achieve the best separation effect.

How SECCO mass works

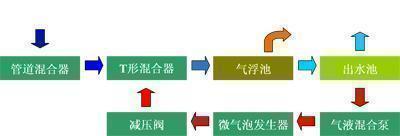

Microbubble generation system produces different density in two stages of wastewater treatment. First, adhesive bubbles are generated in the first stage, and then the surface is collected in the second stage. There is a pressure spiral gas dissolving device in the SECCO mass system, which can use natural control or other gases as the carrier of air flotation.

The reasonable air dissolving device makes the system have 5 times of air dissolving efficiency of traditional air flotation device, and the internal pressure of the system ensures that the air is completely dissolved in water instead of simple mixed contact. The working pressure of microbubble generation system is more than twice that of the traditional air flotation system, so more bubbles will be generated to adhere to the suspended solids, tiny oil particles, floating oil and other components in the water. The microbubble generator is fixed. The water containing a large number of high-density microbubbles is fully mixed with the treated water in the t-mixer, and flows into the separation tank naturally with a small pressure (generally 0.2-0.8kg), so it does not need to spend much maintenance cost.

In order to enhance the separation effect, in addition to the use of air, chemical agents (such as flocculant or coagulant) can also be added to assist the generation of floccules that are more easily adhered by bubbles, so that pollutants can be removed in the bubble separation process.

In the microbubble separation system, we can also effectively use other gases to remove COD, BOD, SS, etc., so that the effluent can meet the discharge requirements of relevant regulations. In special environment, we can also use methane instead of air as the carrier to conduct more thorough treatment of hydrocarbons and floating oil.

Standard flow chart of Saike mass industrial application

Schematic diagram of seck mass separation system

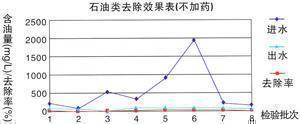

Reference data of removal effect of some water quality bidding

Processing items | COD(Subscript Cr) | SS | Petroleum | turbidity |

Removal rate | Up to 85% | Up to 90% | Up to 95% | Up to60% |

/ | Raw water not more than 20000 ppm | / | / |

System technical parameters

| working pressure | Gas liquid mixing pump 1.0MPa |

| Lift pump 0.02-0.1mpa | |

| Maximum operating temperature | 60 ° C |

| About 5 microns | |

| Depending on the specification of gas-liquid mixing pump | |

| About 25% of the total treated water | |

| One cubic meter of sewage per unit volume, air demand about 35L | |

| PLC,VVVF,PROFIBUS(fully automatic or manual control) | |

| Material of key parts of equipment | Microbubble generatorST/ST304,316 |

| T mixer ST/ST304,316 | |

| Bubble diffusion disk ST/ST304,316 | |

| Air flotation tank St / st304316 | |

| Oil scraper NBR | |

| Surface oil collector PVC, St / st304, or steel belt scraper |

System specifications

No | Capacity / ton / hour | Power / kw | Equipment installation size / M | control mode |

1 | 2 | 2.2 | 1.2×2.0×1.8 | Manual or PLC |

2 | 30 | 11.0 | 3.0×5.0×3.0 | Manual or PLC |

3 | 100 | 22.0 | 4.0×6.0×3.8 | Manual or PLC |

4 | 200 | 37.0 | 5.0×8.0×5.0 | Manual or PLC |

5 | 300 | 55.0 | 6.0×9.0×6.0 | Manual or PLC |

Performance comparison between SECCO mass and traditional air flotation equipment

Energy consumptionWorking pressure (MPA)Bubble size (μ m)Dissolved gas efficiency (%)

performance parameter | Type of air flotation equipment | |||

Mechanical air flotation | electrolytic flotation | Pressurized dissolved air flotation | SECCO mass | |

Water treatment capacity (m3 / h) | 10~1000 | 10~20 | 5~150 | 1~5000 |

Reflux ratio (%) | -- | -- | 50~80 | 20~25 |

area covered | in | in | large | Small |

large | Very large | large | Small | |

0.02 | 0.04 | 0.40 | 1.00 | |

greater than100 | 2~15 | 40~120 | 5 | |

30~50 | 80~90 | 65~85 | 90~95 | |

Dissolved air ratio (L / m3, 20 ℃) | 20~30 | -- | 10~15 | 30~35 |

Hydraulic retention time (min) | 2~3 | 30~60 | 60~150 | 18~25 |

Surface load (m3 / m2. H) | 4~5 | 5~6 | 8~9 | |

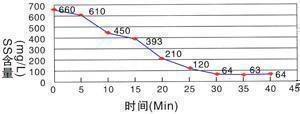

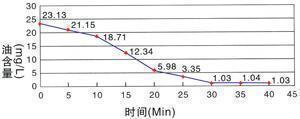

1. Anshan Iron and Steel Group Company - wastewater treatment station of hot rolled thick plate plant

Industrial testing machine: mass-01-01-1.3

Water output: 2.3m3/h

Water temperature: 30 ℃

Raw water SS: 659mg / L

Effluent SS: 64mg / L

Raw water oil: 23.12mg/l

Effluent oil: 1.03mg/l

PH value: 7-8

| Curve of total suspended solids and treatment time: | Curve of relationship between treatment time and oil content: |

|

|

| |

1. Anshan Iron and Steel Group Company - wastewater treatment station of hot rolled thick plate plant

Industrial testing machine: mass-01-01-1.3

Water output: 2.3m3/h

Water temperature: 30 ℃

Raw water SS: 659mg / L

Effluent SS: 64mg / L

Raw water oil: 23.12mg/l

Effluent oil: 1.03mg/l

PH value: 7-8

|

|

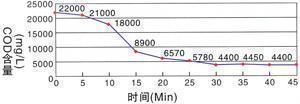

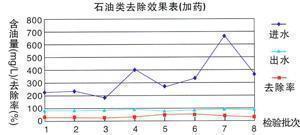

3. Sinopec Jinan Branch Jinan Refinery Wastewater Treatment Station

Industrial testing machine: mass-01-01-1.3

Water output: 2.0m3/h

Water temperature: 35 ℃

Agent Name: polyacrylamide

| |

Application scope of seck-vgs vertical gravity separator

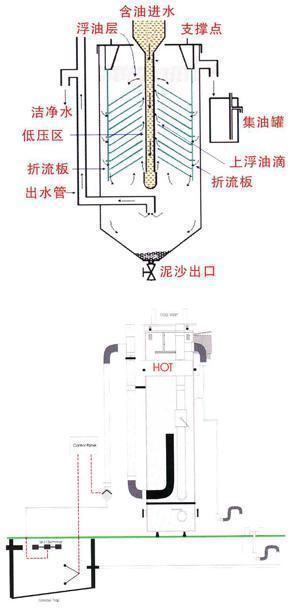

Seck-vgs vertical gravity separator is a vertical column multi-stage oil-water separator, which adopts the basic principle of gravity floating to separation.

Seck-vgs vertical gravity separator has been recommended as the most excellent equipment in the same product by the relevant water department in many practical applications.

The vertical gravity separator of secco-vgs can be divided into:

1. Seck-vgs is mainly used for the treatment of emulsified oil and water mixed liquid of hydrocarbon.

——Crude oil refining and process water recovery

——Mechanical workshop and traffic equipment maintenance

——Maintenance service station and water treatment

——Metalwork and recycling

——Power plant and water restoration system

2. Seck-vgs mainly deals with fat, oil and grease produced in food processing technology

——Hotel and food processing

——Shopping malls and hotels

——Sports venues and leisure places

——Mine and hospital care

——University and factory dining room

Both of the above separators can be supplied in a complete set, including oil float collector and pressure pump. In addition, the seck-vgs can also be used as an auxiliary device of other systems.

How does SECCO VGS work Under the action of slow flow rate and pressure, the oily sewage entering into seck-vgs flows through resonance and a series of upward spiral lipophilic baffles; this process makes the solid suspension with high specific gravity settle into the bottom mud head of seck-vgs, and the fine dispersed oil particles gradually combine into large oil beads under the action of baffles so that their buoyancy in water can lift them to With the increase of the floating oil in the upper part of the tank, the automatic liquid level regulating system can make it flow into the oil collecting tank naturally, and the clear liquid after the treatment of the lower layer of the tank can also be discharged through such liquid level system, and the treated water can be recycled and utilized. For large flow sewage with high treatment requirements, the floating oil collection system of secco-vgs can be completed by a surface floating oil collector, which is a floating device. It has a few millimeters contact with the liquid level surface, which can completely collect the floating oil on the surface, and then send the floating oil to the storage tank outside the system through a small oil pump. The oil in the storage tank can be dewatered by gravity again, and the water in the lower layer can be pumped into the secco-vgs by the oil pump for continuous circulation treatment.

Main features of seck-vgs Advanced and unique design, easy to install and use Low price, simple maintenance and operation Good mobility and processing effect At the same time, unsafe substances are removed to produce crude oil and purified water It can be full St / St or full plastic Fully automatic control, control of fungus regeneration |  |

Partial application of oil-water separation system of SECCO mass induced cyclone

|

|

|