RJ type constant pressure heat exchange unit (hereinafter referred to as RJ unit) is a complete set of equipment that integrates heat exchange, circulation, filtration, pollution prevention, constant pressure and electrical control in the water system of air conditioning (heating) thermal power station. This unit not only includes all the supporting equipment in the general thermal power station, but also the expansion and constant pressure water supplement facilities. In the past, the expansion water tank of the hot water system was placed on the top of the building near the thermal power station, which is highly suitable for the height. Later, the nitrogen filled diaphragm tank which can be placed under was adopted, but it is difficult to be assembled with other equipment due to its huge size. The HD constant pressure device manufactured by Barth company in Germany, which is the agent of our company, is connected to the atmosphere between its expansion volume and not filled with nitrogen, so its body shape is only 1 / 3 of that of the nitrogen filled diaphragm tank, and it is equipped with microcomputer full-automatic control, with high technical content. Because of its small body shape, the shape of the unit is not large, which is the feature of this unit.

The unit can be used as steam water heat exchange or water water heat exchange. It can also be used for 7 / 12 → 8 / 13 ℃ conversion of air conditioning cold water system, so as to avoid the pressure of primary side refrigeration system. The temperature of water supply and return at the secondary side of the unit shall be set by the engineering design unit. In addition to the 95 / 70 and 60 / 50 ℃ listed in this sample, there may be 60 / 55, 55 / 45, 50 / 40, 9 / 14 And so on. The supporting equipment and unit engineering design unit of the unit can also put forward specific opinions on the list of basic design conditions.

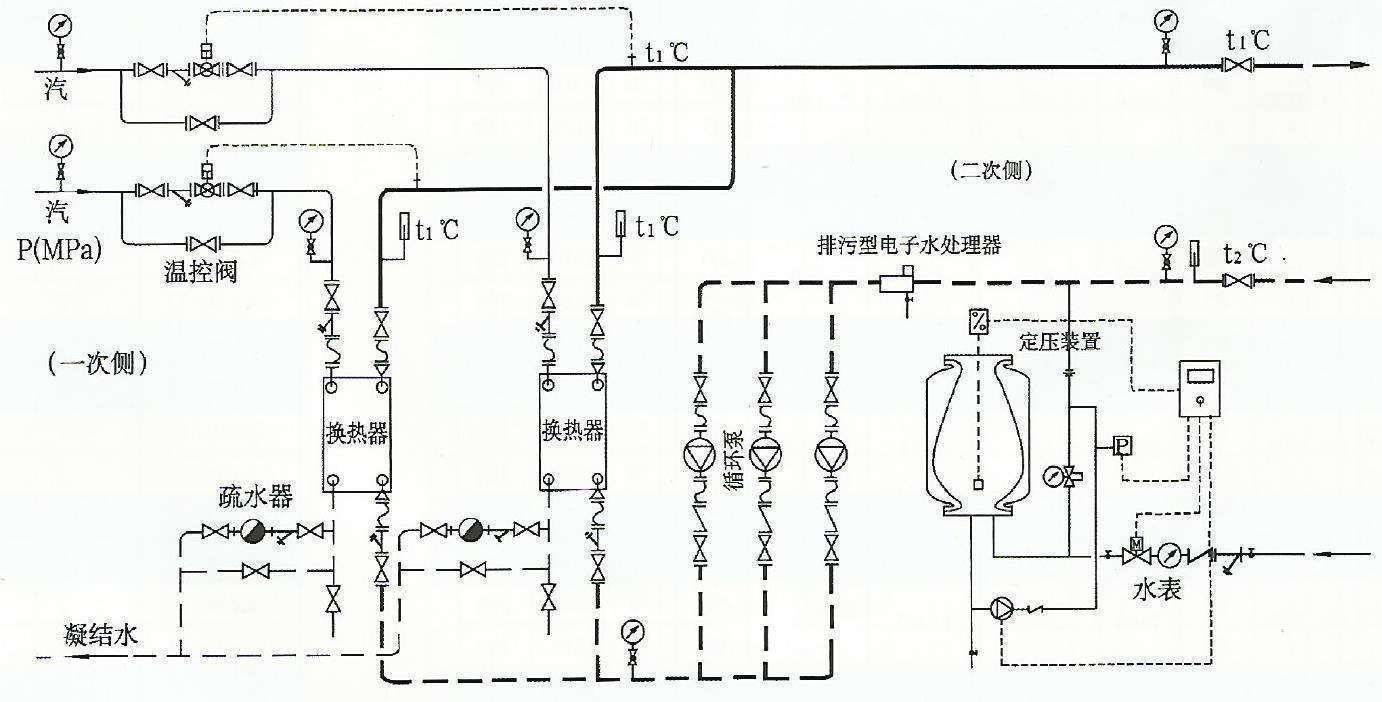

There are many kinds of systems in unit 1. The following figure shows a representative system (2 plate exchange - 3 pumps - 1 set of constant pressure device) for reference

(1) Generally, the heat exchanger is equipped with brazed or assembled plate heat exchanger produced in Germany, Sweden and other European countries。

(1) Generally, the heat exchanger is equipped with brazed or assembled plate heat exchanger produced in Germany, Sweden and other European countries。

(2) Temperature control valve and steam trap shall be equipped with European, American, Japanese or domestic products as agreed in the contract.

(3) The applicable pressure of the circulating pump unit shall be provided with specific data by the engineering design unit. If there is no other specified requirement, it shall be configured at our discretion. One standby pump is set in the pump set.

(4) Constant pressure device HD constant pressure device manufactured by German Barth company is an ideal renewal product of expansion water tank, so this unit is equipped with this device, which has incomparable characteristics with similar products;

A the expansion tank is a diaphragm tank. The expansion water enters into the inner chamber of the diaphragm, and the interlayer between the diaphragm and the steel tank is open to the atmosphere. Therefore, the tank is an atmospheric pressure vessel without pressure. Because there is no inflation space in the tank, its effective volume ratio is 95%, while the effective volume ratio of the general nitrogen filled diaphragm tank is only about 30%;

B. the diaphragm has excellent flexibility, fatigue test up to 4.5 million times, and it does not need to be replaced for use all the year round;

C. high constant pressure accuracy △ P ± 0.1bar (1m water column);

D. equipped with a microcomputer, the operation condition can be adjusted with the change of relevant factors of the project, such as adding floors to the building, lifting the highest point of the system, and increasing the set pressure as required;

E. after the device is put into operation, the actual operating conditions of the system will be displayed at any time, such as the actual operating pressure P at the constant pressure point, the instantaneous water storage% in the diaphragm chamber, and the cumulative value m3 of the system leakage water replenishment, providing key information for scientific management.

Serial number | Unit model | Total thermal power | One time measurement steam | Secondary measurement water | Main supporting equipment | ||||||||

| Plate heat exchanger | |||||||||||||

| G | DN | t1 | t2 | Q | DN | Supplier | Model / pieces | Number of tables | |||||

| KW | 104Kcal/h | kg/h | mm | ℃ | ℃ | t/h | mm | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||

| 1 | RJ-233- | 60 | 233 | 20 | 354 | 50 | 60 | 50 | 20 | 80 | OTTO (Germany)

SWEP(Sweden)

thermo wave (Germany)

And others | OLC85/30 | 1 |

| 95 | 95 | 70 | 8 | 65 | B12/20 | 1 | |||||||

| 2 | RJ-465- | 60 | 465 | 40 | 707 | 65 | 60 | 50 | 40 | 100 | OLC85/60 | 1 | |

| 95 | 95 | ||||||||||||