Preface

With the continuous development of national economy and the continuous improvement of living requirements, the configuration of construction equipment is also becoming increasingly perfect. Originally, only hotels were equipped with central domestic hot water supply system. At present, residential quarters, student apartments and other centralized hot water supply have started, and there are many application examples. In recent years, our company has cooperated with relevant design institutes for many times to accept such orders. On this basis, in order to adapt to the emerging market demand, after a stage of technical preparation and market investigation, we decided to develop RS type complete hot water supply unit in series.

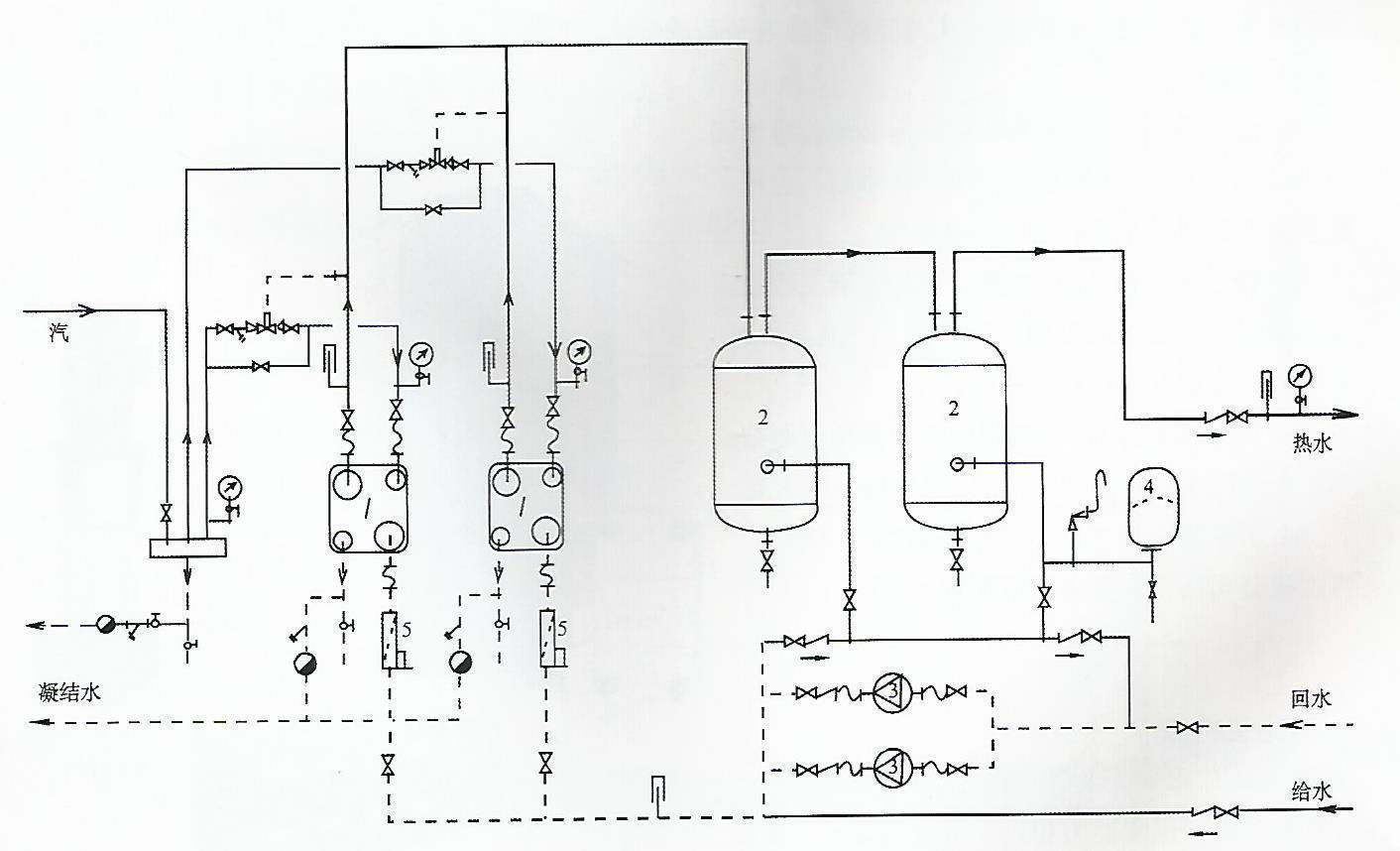

Device configuration

According to the type of heat medium, the device is divided into two heat exchange modes: "steam water" and "water water". The water supply system can be divided into two types: water storage type and direct supply type. The former is equipped with a certain volume of hot water storage vessel, while the latter can meet the requirement of 24-hour constant pressure and variable flow supply of domestic hot water without water storage vessel on the premise that the hot medium can guarantee the day and night supply.

The device will be configured according to the needs of the actual project: heat exchanger, pressure reducing valve, temperature control valve, steam trap, water reservoir, delivery pump, circulating pump, electronic water processor, water separator, water collector, frequency conversion control cabinet and pipe fittings, rack and other equipment or units, as follows:

1. The heat exchanger is generally equipped with assembled or brazed plate heat exchanger made in Europe in the water storage system. In the direct supply system, it is equipped with the bundle type fast water heater made in the United States.

2. When the pressure reducing valve's heat medium is steam or direct water supply mode, it shall be equipped to ensure the smooth operation of tube bundle heat exchanger under low steam pressure condition. The pressure reduction ratio is generally 4:1, 3:1, 2:1 for domestic ones, and 10:1 for imported ones.

3. The hot water outlet temperature of the temperature control valve plate heat exchanger is generally controlled at about 65 ℃, and temperature control valves are required. However, the bundle type fast water heater produced in the United States has its own differential pressure membrane valve which can quickly adjust the outlet water temperature with the change of load without lag, so there is no need for another temperature control valve.

4. The steam trap can be configured as usual, but the drain valve must be installed.

5. The water reservoir is generally equipped with stainless steel combined water tank, or vertical or horizontal water tank, with optional material.

6. The capacity and lift of delivery pump and circulating pump shall be proposed by the engineering design unit, more suitable for the actual needs of the project. The product brand can be equipped with three grades: domestic, joint venture and import.

7. The electronic water processor is mainly used to prevent scaling on the surface of heat exchange. The daily consumption of domestic water is large and the cost of chemical treatment is too high.

8. Water separator, water collector, frequency conversion control cabinet Wait a moment, our company will arrange it according to the contract

。

Device features

1. If the water supply capacity required by the specific project to shorten the design period is similar to the water supply capacity of the unit series, it can be directly used, greatly reducing the design work amount.

2. Shortening the construction period of the project provides material guarantee for speeding up the installation progress.

3. The supplier with flexible configuration can adjust the system configuration according to different requirements of the demander.

4. The main equipment selection shall be reasonable, and the supplier shall have sufficient time in advance to make comprehensive technical and economic optimization for all kinds of supporting equipment of the device, and propose the best configuration.

Ordering procedure

1. First of all, the demander is requested to fill in the basic conditions for design of RS type hot water supply complete unit (for unknown information, please call for consultation) and fax it to our company, or the supplier will send personnel to meet with us.

2. After receiving the basic conditions for design of RS type hot water supply complete unit, our company will give feedback by fax or express within the shortest period of time: device configuration scheme; diameter, orientation and elevation of main connecting pipe; consumption of public works; requirements for station building area and room height, and can offer quotation.

3. Both parties shall conduct design liaison as agreed. Agree on technical parameters and details of the plant.

4. Signing

5. The supplier shall carry out detailed design according to the conditions of civil engineering and public works provided by the demander.

6. Supply according to the contract. Design documents shall be submitted together.

(汽-水)闭式带贮藏罐热水供应系统

参数表

| Model | 60 ℃ hot water supply capacity | Hot coal type | water supply mode | Main equipment selection | |||||||

| Qs | Qh | Residential area | hotel | hotel | Heat exchanger | water storage tank | |||||

| L/S | m3/h | 户 | 人 | 床 | 床 | type | Number of tables | m3 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| RS-0.5 | 0.5 | 1.8 | 4 | 14 | 8 | 7

| 0.4MPa steam | Water storage type | Omc60/24 | 1 | 0.6 |

| Direct supply | 415 | 1 | - | ||||||||

| water90/70 | Water storage type | B12/30 | 1 | 0.6 | |||||||

| RS-1 | 1 | 3.6 | 11 | 39 | 30 | 15 | 0.4MPa steam | Water storage type | Omc60/40 | 1 | 1.2 |

| Direct supply | 415 | 1 | - | ||||||||

| water90/70 | Water storage type | B12/50 | 1 | 1.2 | |||||||

| RS-2 | 2 | 7.2 | 40 | 140 | 120 | 32 | 0.4MPa steam | Water storage type | Omc85/30 | 1 | 2.4 |

| Direct supply | 535 | 1 | - | ||||||||

| water90/70 | Water storage type | B60/20 | 1 | 2.4 | |||||||

| RS-3 | 3 | 10.8 | 80 | 280 | 280 | 72 | 0.4MPa steam | Water storage type | Omc85/50 | 1 | 3.6 |

| Direct supply | 665 | 1 | - | ||||||||

| water90/70 | Water storage type | B60/30 | 1 | 3.6 | |||||||

| RS-4 | 4 | 14.4 | 130 | 455 | 500 | 128 | 0.4MPa steam | Water storage type | Omc85/30 | 2 | 4.8 |

| Direct supply | 665 | 1 | - | ||||||||

| water90/70 | Water storage type | B60/30 | 1 | 4.8 | |||||||

| RS-6 | 6 | 21.6 | 246 | 861 | 1110 | 280 | 0.4MPa steam | 储水式 | Omc85/40 | 2 | 7.2 |

| Direct supply | 535+665 | 1+1 | - | ||||||||

| water90/70 | Water storage type | Gx-12/47 | 1 | 7.2 | |||||||

| RS-8 | 8 | 28.8 | 380 | 1330 | 1975 | 512 | 0.4MPa steam | Water storage type | Omc85/60 | 2 | 9.5 |

| Direct supply | 665 | 2 | - | ||||||||

| water90/70 | Water storage type | Gx-26/39 | 1 | 9.5 | |||||||

| RS-10 | 10 | 36 | 520 | 1820 | 3086 | 800 | 0.4MPa steam | Water storage type | Omc85/50 | 3 | 11.9 |

| Direct supply | 665+535 | 2+1 | - | ||||||||

| water90/70 | Water storage type | Gx-26/49 | 1 | 11.9 | |||||||

| RS-12 | 12 | 43.2 | 670 | 2305 | 1152 | 0.4MPa steam | Water storage type | Omc85/60 | 3 | 14.3 | |

| Direct supply | 665 | 3 | - | ||||||||

| water90/70 | Water storage type | Gx-12/47 | 2 | 14.3 | |||||||

| RS-15 | 15 | 54 | 900 | 3150 | 1800 | 0.4MPa steam | Water storage type | Omc85/80 | 3 | 17.8 | |

| Direct supply | 8120 | 2 | - | ||||||||

| water90/70 | Water storage type | Gx-12/61 | 2 | 17.8 | |||||||

| RS-18 | 18 | 64.8 | 1180 | 4130 | 2592 | 0.4MPa steam | Water storage type | Omc85/60 | 4 | 21.4 | |

| Direct supply | 8120+665 | 2+1 | - | ||||||||

| 水90/70 | Water storage type | Gx-26/45 | 2 | 21.4 | |||||||

| RS-21 | 21 | 75.6 | 1440 | 5040 | 0.4MPa steam | Water storage type | Omc85/80 | 4 | 24.9 | ||

| Direct supply | 8120 | 3 | - | ||||||||

| water90/70 | Water storage type | Gx-26/53 | 2 | 24.9 | |||||||

| RS-24 | 24 | 86.4 | 1720 | 6020 | 0.4MPa steam | Water storage type | Omc85/100 | 4 | 28.5 | ||

| Direct supply | 8120+535 | 3+1 | - | ||||||||

| water90/70 | Water storage type | Gx-26/54 | 2 | 28.5 | |||||||

续表

| Main equipment selection | Secondary side supporting unit | Area of station building | ||||||||||||

| Delivery pump | Circulating pump | Pressure reducer | Temperature control valve | Steam trap | Electronic water processor | Water separator | manifold | FminM2 | ||||||

| QAM3/H | HmH2O | Number of units (operation / standby) | QAM3/H | HmH2O | Number of units (operation / standby) | |||||||||

| 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 |

| 2 | 15~30 | 2 | 1/1 | 1 | 8~15 | 1 | - | ● | ● | ● | 9 | |||

| ● | ● | ● | ● | 3.2 | ||||||||||

| ● | ● | ● | 9 | |||||||||||

| 4 | 15~35 | 2 | 1/1 | 2 | 8~18 | 1 | - | ● | ● | ● | 10 | |||

| ● | ● | ● | ● | 3.2 | ||||||||||

| ● | ● | ● | 10 | |||||||||||

| 8 | 20~40 | 2 | 1/1 | 4 | 10~20 | 1 | - | ● | ● | ● | 11 | |||

| ● | ● | ● | ● | 4.1 | ||||||||||

| ● | ● | ● | 11 | |||||||||||

| 12 | 20~45 | 2 | 1/1 | 6 | 10~22 | 2 | 1/1 | ● | ● | ● | 13.5 | |||

| ● | ● | ● | ● | 5.0 | ||||||||||

| ● | ● | ● | 13.5 | |||||||||||

| 15 | 15~30 | 2 | 1/1 | 8 | 12~25 | 2 | 1/1 | ● | ● | ● | 14.5 | |||

| ● | ● | ● | ● | 5.0 | ||||||||||

| ● | ● | ● | 14.5 | |||||||||||

| 12*2 | 25~50 | 3 | 2/1 | 12 | 12~25 | 2 | 1/1 | ● | ● | ● | ● | ● | 16.5 | |

| ● | ● | ● | ● | ● | ● | 5.0 | ||||||||

| ● | ● | ● | ● | ● | 17 | |||||||||

| 15*2 | 20~70 | 3 | 2/1 | 15 | 15~30 | 2 | 1/1 | ● | ● | ● | ● | ● | 19 | |

| ● | ● | ● | ● | ● | ● | 5.0 | ||||||||

| ● | ● | ● | ● | ● | 20 | |||||||||

| 20*2 | 30~70 | 3 | 2/1 | 20 | 15~35 | 2 | 1/1 | ● | ● | ● | ● | ● | 20 | |

| ● | ● | ● | ● | ● | ● | 7.5 | ||||||||

| ● | ● | ● | ● | ● | 21 | |||||||||

| 24*2 | 35~80 | 3 | 2/1 | 24 | 17~40 | 2 | 1/1 | ● | ● | ● | ● | ● | 21 | |

| ● | ● | ● | ● | ● | ● | 8.0 | ||||||||

| ● | ● | ● | ● | ● | 23 | |||||||||

| 20*3 | 35~80 | 4 | 3/1 | 30 | 18~40 | 2 | 1/1 | ● | ● | ● | ● | ● | 24 | |

| ● | ● | ● | ● | ● | ● | 7.5 | ||||||||

| ● | ● | ● | ● | ● | 26 | |||||||||

| 24*3 | 40~80 | 4 | 3/1 | 18*2 | 20~40 | 2 | 2/1 | ● | ● | ● | ● | ● | 25 | |

| ● | ● | ● | ● | ● | ● | 8.0 | ||||||||

| ● | ● | ● | ● | ● | 27 | |||||||||

| 28*3 | 40~80 | 4 | 3/1 | 20*2 | 20~40 | 3 | 2/1 | ● | ● | ● | ● | ● | 26 | |

| ● | ● | ● | ● | ● | ● | 9.0 | ||||||||

| ● | ● | ● | ● | ● | 28 | |||||||||

| 24*3 | 40~80 | 4 | 3/1 | 24*2 | 20~40 | 3 | 2/1 | ● | ● | ● | ● | ● | 31 | |

| ● | ● | ● | ● | ● | ● | 10.0 | ||||||||

| ● | ● | ● | ● | ● | 33 | |||||||||