Application scope:

*Cooling water: cooling tower, air conditioning system, refrigeration system, make-up water system, DC system.

To reduce the formation of deposits on the heat exchanger, so as not to affect the cooling effect of the heat exchanger.

~ prevent scaling, spots and corrosion.

- prevent equipment failure and reduce equipment maintenance.

*Equipment protection:

~ protect nozzles, solenoid valves, water pumps and bearings, ion exchangers, sealing elements, and avoid blocking of pipelines, nozzles and other important equipment.

*Water supply:

Filter surface water, river water, reservoir water, lake water, pool water, sea water and underground water to remove sand, bacteria, algae, organic matter, iron filings, sulfur

- reduce chemical and chlorine treatment.

*Reuse of circulating water: it is used for filtration and reuse of industrial water in metallurgy, chemical industry, electronics, power, food, papermaking, sugar industry, etc., especially for the protection of spray nozzle crystallizer in iron and steel system.

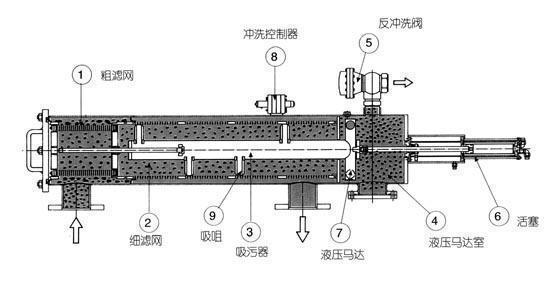

*Wastewater treatment: To reduce the cost of fine filtration system. When the water passes through the coarse filter screen ① of the filter, it enters the fine filter chamber and gradually accumulates a layer of dirt on the fine filter screen ②. This will cause a pressure difference between the inner and outer surfaces of the fine screen. When the pressure difference reaches a predetermined value, the cleaning cycle begins. |

|

Cleaning cycle:

Flush controller ⑧ controls backwash valve ⑤ and piston ⑥, and water flows out of hydraulic motor chamber ④ through backwash valve. When the backwash valve is opened, the pressure in the hydraulic motor chamber ④, the suction cleaner ③, and the suction nozzle drops to be connected with the atmosphere. In this way, there is a pressure difference between the outside (clean water) of the fine filter screen ② and the inside (dirty water) of the fine filter screen opposite to the suction nozzle, and the backwash movement cleans out the filter screen area opposite to the suction nozzle. When water and dirt pass through hydraulic motor ⑦, it drives the dirt absorber to rotate, and at this time, the piston is also driven to move axially. The axial and rotary movement of the suction nozzle can clean the whole filter screen.

When the dirt on the filter net is washed out, the pressure difference disappears. The flushing controller closes the backwash valve and the piston returns to its original position. The system starts to prepare for the next flushing cycle.

|

|

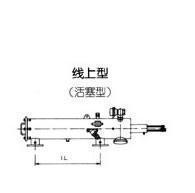

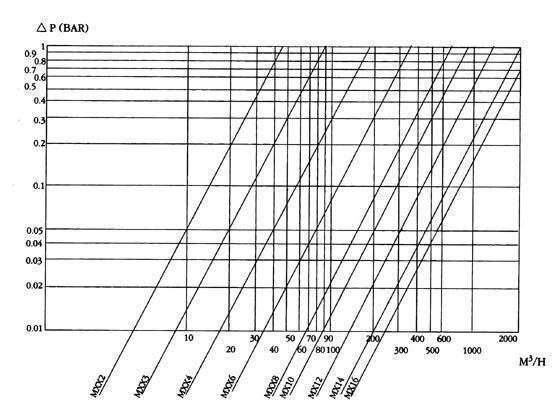

M3 series and M4 series can be divided into standard type, high pressure type and high temperature type. Standard type: the maximum working pressure is 10 bar, the maximum working temperature is 65 ℃; the maximum working pressure of high pressure type is 16 bar; the maximum working temperature of high temperature type is 98 ℃

|

|

|

| No. model flow m3 / h screen area cm2 installation length mm weight kg flat screen wave type1M302L254101230580602M302404101230604713M30480770231074895 | No. model flow m3 / h filter screen area cm2 installation length mm weight kg flat filter screen wave type 1m302lp254101230150602m302p404101230205713m304p80770231030095 | 序号型号流量m3/h滤网面积cm2安装长度mm重量kg平滤网波型1M403P404101230205952M404P807702310300115 |

|

|

|

| 序号型号流量m3/h滤网面积cm2安装长度mm重量kg平滤网波型1M302LPE25153046004501402M303LP40153046004501853M302LPE40153046004502454M304LP80306092009002865M304LPE80153046004502556M306P150153046004502887M306PE150153046004503088M306PP150306092009003509M306XLP12046001380090035910M308P3003060920090043511M308PP30046001380090062512M310P400408012300110083013M310PP4006100183001100108014M312P6006100183001100125015M314P9006900205001270134516M316P110069002050012701885 | 序号型号流量m3/h滤网面积cm2安装长度mm重量kg平滤网波型1M403LP40153046004501602M404LPE40153046004502103M404LP80306092009002854M404LPE80153046004503555M406P150153046004503856M406PE150153046004504057M406LP150306092009004758M406XLP1204600138009004909M408P3003060920090054510M408LP30046001380090056811M410P400408012300110086512M410LP400610018300110090513M412P6006100183001100138014M414P9006900205001270156015M416P110069002050012701985 |

Maximum working pressure: M3 series standard type: 10bar high pressure type: 16bar M4 series standard type: 10bar high pressure type: 16bar Minimum pipe pressure required during flushing: 2.5bar Maximum working temperature: 65 ℃ Approximate flushing cycle time: Non piston: 3-5 seconds; piston: 8-18 seconds. Optional screen accuracy: Flat screen: 50, 8010012015020040080015003000 μ M Wave net: 15, 25, 30, 40, 50, 80100120150200 μ M Inlet / outlet flange standard: ASA, bstd, BstE, din10, jisk10, others Control mode: Full automatic hydraulic control, electronic control, manual control

|

|